Power Rear Bracket

Power Rear Bracket Specification

- Machine Type

- CNC Milling Machine

- Thread Type

- Metric Threaded Holes

- Load Capacity

- Up to 100 kg

- Hardness

- HRC 38-42

- Coating

- Corrosion Resistant Treatment

- Weight

- 950 g

- Accuracy

- High Dimensional Accuracy

- Cutting Speed

- 180 m/min

- Size

- 150 mm x 80 mm x 35 mm

- Method

- Machined and Powder Coated

- Spindle Speed

- 4500 rpm

- Shape

- Rectangular with Slots

- Type

- Mounting Bracket

- Material

- High-Strength Steel

- CNC

- Yes

- Tolerance

- ±0.02 mm

- Surface

- Powder Coated

- Use

- Automotive Mounting

- Application

- Rear Electrical Power Assembly

- Usage & Applications

- Powertrain Support, Electrical Securement

- Packaging

- Individually shrink-wrapped, boxed

- Impact Strength

- Withstands impact up to 30 joules

- Shelf Life

- 10 years under recommended conditions

- Corrosion Resistance

- Salt spray tested for 500 hours minimum

- Fire Resistance

- Meets UL94 V-0 rating

- Temperature Range

- -40°C to 120°C

- Mounting Holes

- 4 x 10 mm countersunk holes for firm attachment

- Color

- Black

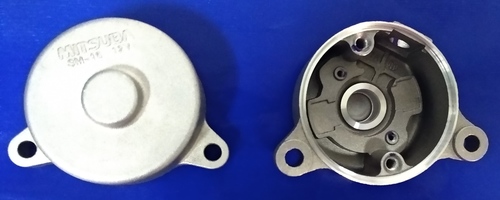

About Power Rear Bracket

Our remarkable product array includes the best quality Rear Bracket that is used as an outer cover of self starter motor. The offered bracket is widely demanded in automobile industry. Manufactured in accordance with set market standards, our team of deft professionals uses utmost quality raw materials and advanced technology to make this bracket. In addition, this Rear Bracket can be availed from us in different sizes and finishes at market leading prices.

Features:

-

Rugged design

-

Accurate dimensions

-

Easy installation

-

Reliable operations

Precision Engineering for Reliable Performance

Each Power Rear Bracket undergoes CNC machining for high dimensional accuracy and superior consistency. The precision of 0.02 mm ensures a perfect fit, critical for automotive applications demanding high reliability and safety standards. Powder coating enhances surface durability, adding a protective layer against environmental stress.

Built for Extreme Automotive Environments

This bracket excels in harsh operational settings, thanks to its salt spray-tested corrosion resistance, robust impact absorption up to 30 joules, and a wide temperature adaptability from -40C to 120C. The UL94 V-0 fire resistance rating offers additional safety assurance when used for electrical power assemblies.

Versatile Mounting and Application Support

Designed for simple installation, the brackets 4 x 10 mm countersunk holes allow for a firm, secure attachment, while its metric threaded holes and rectangular slotted shape offer flexibility for various configurations. It supports powertrain components and electrical securement in modern vehicles, maximizing both strength and longevity.

FAQs of Power Rear Bracket:

Q: How is the Power Rear Bracket installed in automotive applications?

A: The Power Rear Bracket is installed using the four 10 mm countersunk mounting holes, which facilitate firm attachment to vehicle structures. Its metric threaded holes also allow for secure fastening of electrical or powertrain components in the rear assembly area.Q: What makes this bracket suitable for harsh environments?

A: Salt spray testing for a minimum of 500 hours ensures strong corrosion resistance, while its powder-coated high-strength steel construction offers superior durability. It also withstands extreme temperatures from -40C to 120C and resists impacts up to 30 joules.Q: When should this bracket be used in automotive installations?

A: This bracket is ideal for use during the mounting of electrical power assemblies or powertrain supports, particularly where high load capacity (up to 100 kg) and precision are required. Its fire and impact resistance make it suitable for safety-critical installations.Q: Where is the Power Rear Bracket most commonly applied?

A: The bracket is predominantly used in the rear compartments of vehicles for securely mounting electrical assemblies and supporting powertrain elements, ensuring reliable operation in both standard and demanding automotive environments.Q: What is the process involved in manufacturing the bracket?

A: Advanced CNC milling machines are used, ensuring dimensional accuracy and a tolerance of 0.02 mm. The bracket is then powder coated and undergoes corrosion-resistant treatment. Each piece is individually shrink-wrapped and boxed for optimal shelf life and protection.Q: How does this bracket benefit automotive manufacturers and installers?

A: Its robust load capacity, precise machining, and long 10-year shelf life provide reliability and reduce maintenance. Its compliance with UL94 V-0 ensures fire safety, while the corrosion-resistant coating and high impact strength enhance longevity and performance.

More Products in CNC Machined Component Category

CNC Machined Front Bracket

Price 30-35 INR

Minimum Order Quantity : 3000 Pieces

Machine Type : 4axis CNC milling

Material : Aluminum alloy (6061T6)

CNC : Yes

Surface : Other , Anodized aluminum

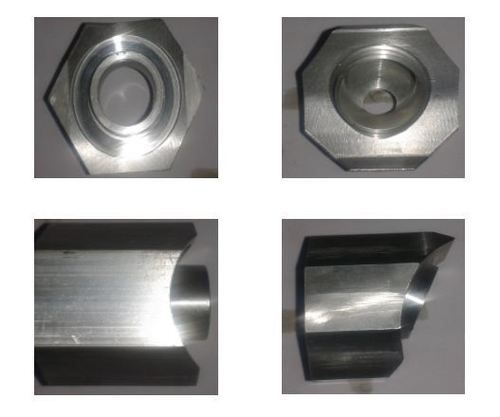

Hexagon & Octagon Components

Price 20-30 INR

Minimum Order Quantity : 3000 Pieces

Machine Type : Milling and Turning Machines

Material : Highgrade stainless steel

CNC : Yes

Surface : Smooth finish, Other

Spindle

Price 30-35 INR

Minimum Order Quantity : 3000 Pieces

Machine Type : CNC Machines

Material : Steel

CNC : Yes

Surface : Other , Smooth

Power Machine Shop Floor

Machine Type : Power Machine Shop Floor Facility

Material : Mild Steel

CNC : Yes

Surface : Other , Polished / Finished

Send Inquiry

Send Inquiry