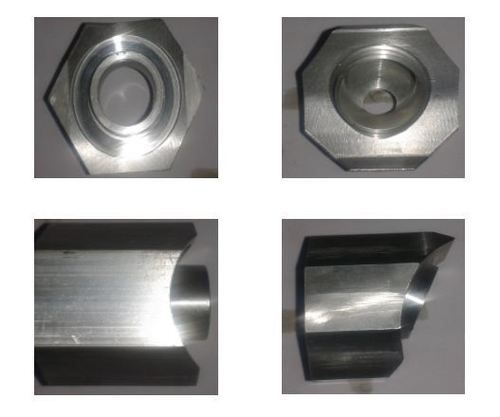

CNC Machined Front Bracket

CNC Machined Front Bracket Specification

- Load Capacity

- 120 kg

- Machine Type

- 4-axis CNC milling

- Cutting Speed

- 2500 mm/min

- Spindle Speed

- 12000 RPM

- Weight

- 0.65 kg

- Hardness

- 92 HB

- Coating

- Clear anodized

- Size

- 150 mm x 80 mm x 35 mm

- Shape

- Custom front bracket

- Accuracy

- High accuracy to ±0.01 mm

- Thread Type

- Metric threads

- Method

- Subtractive CNC fabrication

- Type

- Front bracket

- Material

- Aluminum alloy (6061-T6)

- CNC

- Yes

- Tolerance

- ±0.01 mm

- Surface

- Anodized aluminum

- Use

- Mounting and bracketing components

- Application

- Automotive, industrial machinery

- Usage & Applications

- Used for structural support or mounting purposes

- Packaging

- Individually shrink-wrapped and boxed

- Production Batch

- Custom, low to medium volume

- Edge Finish

- Chamfered edges for safety and aesthetics

- Customizability

- Custom shapes, materials, and finishes available upon request

- Inspection

- 100% dimensional inspection with CMM

- Corrosion Resistance

- Excellent due to anodized surface treatment

- Temperature Resistance

- Up to 120°C continuous use

- Lead Time

- 2-3 weeks for standard orders

- Mounting Holes

- Precision-drilled mounting holes with countersinks

About CNC Machined Front Bracket

As one of the leading manufacturer and supplier of CNC Machined Front Bracket, we have been recognized as one of the prominent entity in this domain. The bracket offered by us is used as a starter motor front cover in various vehicles. This bracket is manufactured by utilizing premium quality raw materials and contemporary techniques under the stern guidance of our deft professionals. We provide this CNC Machined Front Bracket in different dimensions as per specific requirements of our prestigious clients.

Features:

-

Withstand high pressure

-

High strength

-

Easy installation

-

Rust resistance

Premium CNC Machining for Precision Brackets

Our front brackets are manufactured with high-precision 4-axis CNC milling using advanced subtractive fabrication techniques. The process ensures tight tolerances and exceptional repeatability, ideal for applications requiring reliable structural support and accurate mounting.

Built for Safety and Longevity

Each bracket boasts chamfered edges for user safety and a modern look. Made from 6061-T6 aluminum alloy and finished with clear anodizing, it withstands high temperatures up to 120C, resists corrosion, and provides a long-lasting solution for harsh industrial or automotive environments.

Customizable and Quality-Checked

Whether you need unique shapes, materials, or finishes, we accommodate custom requests for brackets and ensure all products meet specifications through comprehensive 100% dimensional inspection via CMM. Each piece is shrink-wrapped and boxed individually for assured delivery quality.

FAQs of CNC Machined Front Bracket:

Q: How is the CNC Machined Front Bracket manufactured?

A: The bracket is produced using a 4-axis CNC milling machine, which employs subtractive fabrication to mill 6061-T6 aluminum alloy with high accuracy, achieving a dimensional tolerance of 0.01 mm. Each part is then anodized and undergoes detailed inspection.Q: What benefits does anodized aluminum provide for this bracket?

A: Anodizing the aluminum surface provides excellent corrosion resistance, enhances the brackets durability, and maintains its appearance over time, even in demanding environmental conditions such as automotive or industrial use.Q: What applications are suitable for this front bracket?

A: This bracket is ideal for mounting and structural support in automotive equipment, industrial machines, and other applications requiring reliable load-bearing performance and high precision.Q: Can I customize the bracket shape, material, or finish?

A: Yes, custom options are available for shape, materials, and surface finishes to meet your specific project requirements. Please contact us with your unique specifications for a tailored solution.Q: How are the brackets inspected for quality?

A: Every bracket undergoes 100% dimensional inspection using a Coordinate Measuring Machine (CMM) to ensure each piece meets strict precision standards before packaging and shipping.Q: What is the typical lead time for standard orders?

A: Standard orders for the CNC Machined Front Bracket are usually fulfilled within 2-3 weeks, depending on volume and customization needs.

More Products in CNC Machined Component Category

Industrial CNC Machined Components

Price 12-40 INR

Minimum Order Quantity : 3000 Pieces

Material : Aluminum Alloy

Method : CNC Milling and Turning

Application : Automotive Industrial Machinery

Size : Variable Precision Engineered

Spindle

Price 30-35 INR

Minimum Order Quantity : 3000 Pieces

Material : Steel

Method : Machining

Application : Rotational Motion

Size : Standard

Hexagon & Octagon Components

Price 20-30 INR

Minimum Order Quantity : 3000 Pieces

Material : Highgrade stainless steel

Method : Precision machining

Application : Industrial machinery components

Size : Various sizes available

Armature Shaft

Price 22-25 INR

Minimum Order Quantity : 3000 Pieces

Material : HighGrade Steel

Method : Forging

Application : Industrial Machinery

Size : Standard and Custom Sizes

Send Inquiry

Send Inquiry