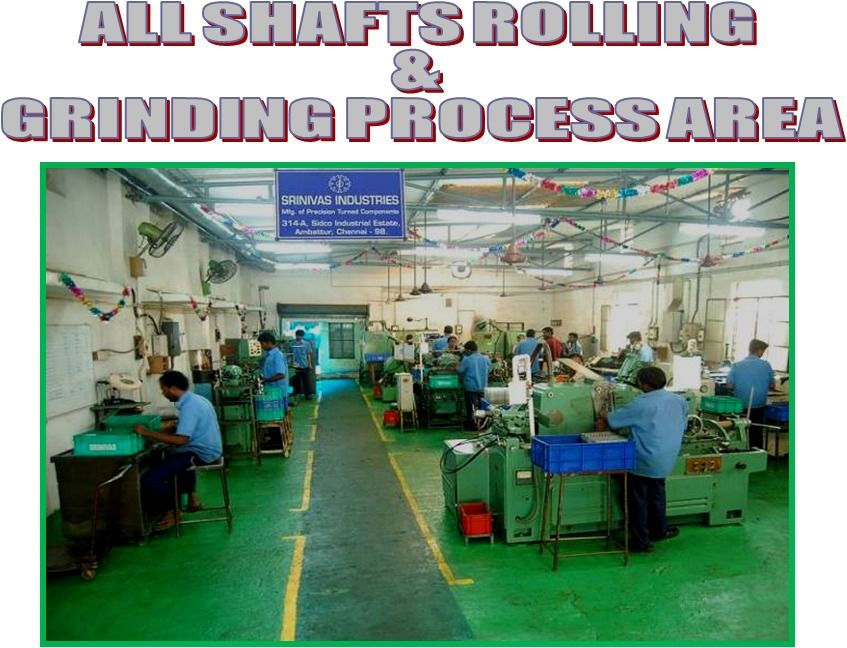

Power Machine Shop Floor

Power Machine Shop Floor Specification

- Machine Type

- Power Machine Shop Floor Facility

- Method

- Conventional & CNC Machining

- Weight

- Approx. 2 Tons

- Cutting Speed

- Up to 1200 RPM

- Coating

- Anti-corrosive Painted Finish

- Thread Type

- Standard Metric

- Load Capacity

- Up to 10 Tons

- Spindle Speed

- Variable, up to 3500 rpm

- Shape

- Rectangular

- Size

- 10 m x 4 m x 0.4 m

- Accuracy

- ±0.01 mm

- Hardness

- 40 - 50 HRC

- Type

- Heavy Duty Shop Floor

- Material

- Mild Steel

- CNC

- Yes

- Tolerance

- ±0.02 mm

- Surface

- Polished / Finished

- Use

- Industrial fabrication and repair

- Application

- Machine shop floor operations

- Usage & Applications

- Machining, Assembly, Heavy Equipment Maintenance

- Edge Type

- Chamfered Edges

- Installation Time

- Less than 24 hours

- Electrical Installation

- Supports heavy-duty power supply

- Safety Features

- Anti-static coating, slip resistance

- Color

- Industrial Grey

- Impact Resistance

- High, suitable for heavy machinery

- Temperature Resistance

- Up to 120°C continuous operation

- Noise Dampening

- Integrated noise reduction layer

- Floor Finish

- Non-slip textured surface

- Maintenance

- Easy Clean, Low Maintenance

About Power Machine Shop Floor

Optimal Usage and Standout Features

Power Machine Shop Floor is tailored for industrial fabrication and repair. Designed for machining, assembly, and heavy equipment maintenance, its surface ensures safety and precision with slip resistance, anti-static coating, and noise reduction. Benefitting from high impact resistance, easy clean maintenance, and quick installation, users experience smooth workflow. Direction of use: Simply lay out and secure for instant heavy-duty application. Compatible with CNC machining, it achieves 0.02 mm tolerance, perfect for demanding shop operations.

Valuation, Transportation, and Certifications

We offer the Power Machine Shop Floor with flexible FOB port options to streamline global transportation. Secure payment terms accommodate various buyer needs, ensuring smooth transaction processes. Each floor undergoes strict certification and quality checks to guarantee first-rate industrial standards. Valuation factors reflect its exceptional durability, safety features, and precision engineering, making it a highly trusted solution for shop floor operations. Reliable shipping and documented compliance further enhance customer confidence.

FAQs of Power Machine Shop Floor:

Q: How is the Power Machine Shop Floor installed, and what is the typical installation time?

A: The Power Machine Shop Floor is designed for efficient installation, taking less than 24 hours. Directions involve preparing the site, placing the floor panels, and securing them to quickly achieve a ready-to-use industrial environment.Q: What types of industrial operations can take advantage of this shop floors features?

A: This shop floor is ideal for machining, assembly, and heavy equipment maintenance. Its robust structure and precision tolerances support both conventional and CNC machining processes in demanding industrial settings.Q: Where does the Power Machine Shop Floor provide the best performance?

A: It excels in machine shop environments, especially where high-temperature operation, noise reduction, and heavy machinery support are essentialfor example, industrial fabrication and repair workshops.Q: What are the maintenance requirements for this shop floor?

A: Maintenance is straightforward, thanks to its easy-clean, low-maintenance surface. Regular cleaning to remove debris and periodic inspection of the anti-static and anti-corrosive coatings keep the floor in optimal condition.Q: How does the anti-static coating and noise reduction layer benefit shop operations?

A: The anti-static coating prevents static buildup, enhancing worker safety and equipment longevity, while the noise reduction layer dampens operational sounds, creating a more comfortable and productive shop floor environment.

More Products in CNC Machined Component Category

CNC Machined Front Bracket

Price 30-35 INR

Minimum Order Quantity : 3000 Pieces

CNC : Yes

Shape : Custom front bracket

Usage & Applications : Used for structural support or mounting purposes

Weight : 0.65 kg

Industrial Precise Turned Components

Price 30-35 INR

Minimum Order Quantity : 3000 Pieces

CNC : Yes

Shape : Customized shapes based on component needs

Usage & Applications : Used in industrial machinery and systems

Weight : Lightweight but durable

Output Shaft

Price 14-18 INR

Minimum Order Quantity : 3000 Pieces

CNC : Yes

Shape : Cylindrical with splines

Usage & Applications : Power transmission in gear systems

Weight : Depends on size

Rear Bracket

Price 40 INR / Piece

Minimum Order Quantity : 3000 Pieces

CNC : Yes

Shape : Rounded bracket

Usage & Applications : Used in machinery for support and alignment

Weight : Lightweight Liter (Ltr)

Send Inquiry

Send Inquiry